Technology

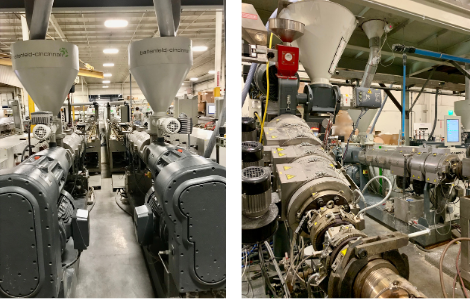

Bavarian Polymers places a large emphasis on high output profile extrusion. Our technology includes dual strand technology with outputs of up to 750 lbs/hour. This extensive tooling technology allows set up on any of our machines or any strand at any time. This particular setup affords us the opportunity for high scheduling flexibility and low inventory.

By focusing our efforts and output solely on window and door extrusions, we have the distinct and unique capability of completing all projects with the highest of efficiency.

In-Line Fabrication

From cap-stocking to punching and weather strip insertion, Bavarian Polymers has the ability to complete any in-line fabrication process for our customers.

High Output Tooling

Our extrusion dies are made of a top quality grade of stainless steel, which allows for high abrasion resistance and therefore consistent product quality. In addition, our extrusion tool capabilities allow for the ability to run any extrusion tool on any extrusion line at any time!

Material Handling

The latest Bavarian Polymers mechanical material handling system allows for homogenous material flow, with incredibly low raw material separation and a spotless working environment.

Quality Control Technology

Through the extensive training of employees and Continuous Quality Control Process, Bavarian Polymers can ensure customer satisfaction through top quality products. Our advanced measuring technologies are implemented to meet and exceed our high quality standards.

Profile Wrapping and Profile Lamination

In addition to its comprehensive window and door systems, Bavarian Polymers offers an extensive range of solid colors and wood grain for interior and exterior applications.

Logistics and Bar Coding

Our profiles are packaged in 16′ metal stackable racks, and each product on said rack is bar coded with information such as:

- Date of production

- Shift information

- Color and total footage

- Profile length and type/part number

- Weight of part and total weight

These racks guarantee the easy movement and shipment of our window and door profile extrusion products.

An AAMA Certified Profile and Extrusion Company

In order to produce our top-of-the-line products, Bavarian Polymers has entered into a strong supply relationship with the world’s largest PVC supplier. As such, our proprietary formulation ensures the following:

- AAMA Certification

- Optimum manufacturing process ability

- Unwavering product quality

- Long-Term performance

AAMA Certified

Profiles are certified for compliance through the AAMA certification program in which randomly-selected production line samples of extrusions are tested by an accredited third-party laboratory for conformance. The requirements include:

- Impact Resistance – impact strength at high and low temperatures

- Heat Resistance – 30 minutes at 300°F

- Dimensional Stability – 30 minutes at 180°F

- Weight Tolerance – (+/- 10%)

In addition to artificial weathering such as QUV and XENON, our profiles are constantly weather tested in Arizona, Florida and Ohio to ensure excellent weatherability.

Solid Color Offerings

- Bright white

- Colonial white

- Sandstone/Tan

- Clay/Earthtone